National Standard Notes on Paints and Paints

Paint in Chinese traditional name for paint.The so-called coating is coated on the surface of the object to be protected o decorated,and can be formed with a strong coating attached to the film,usually in resin,or oil,or emulsion-based,with or without adding pigments,The corresponding additives,with organic solvents or water made of viscous liquid.China's paint industry more authoritative "paint technology"a book is so defined:"paint is a material,this material can be used in different construction process coated on the surface of the object,the formation of a strong adhesion,with a certain strength,continuous A film formed so as to form a film,also known as a film or coating.

Paint composition

Coatings are generally composed of four basic ingredients:film-forming materials(resins),pigments(including physical pigments),solvents and additives.

1、film-forming material is the main component of the coating,including grease,grease processing products,cellulose derivatives,natural resin and synthetic resin.The film-forming material also includes a partially nonvolatile reactive diluent which is the primary material for the formation of a continuous film by coating the coating firmly on the surface to be coated.It is the basis for the composition and determines the basic properties of the coating.

2、additives such as defeaters,leveling agents,etc.,there are some special functional additives,such as substrate wetting agent.These adjuvants generally do not form a film,but the base material to form a coating process and durability plays a very important role.

3、pigments are generally divided into two kinds,one for the color pigments,common titanium dioxide,chrome yellow,etc.,there are kinds of physical pigments,that is often said that the filler,such as calcium carbonate,talc 4 Solvents include hydrocarbon solvents(mineral oil,kerosene,gasoline,benzene,toluene,xylene,etc.),alcohols,ethers,ketone and esters.The main effect of the solvent and water is to disperse the film-forming base to form a viscous liquid.It contributes to the construction and improvement of certain properties of the coating.According to the main coating material used in the coating materials can be divided into oily coatings,fiber coatings,synthetic coatings and inorganic coatings;according to paint or paint film separable solution,latex,sol,powder,light,extinction and colorful art paint.

Common variety There are many methods of classification of paint,usually the following classification methods:

(1) according to the form of paint can be divided into water-based paint,solvent coatings,powder coatings,high solids coating;

(2) according to the construction method can be divided into brush coating,spray coating,roll coating,dip coating,electrophoretic coating;

(3) according to the construction process can be divided into primer,in the paint(two primer),topcoat,varnish;

(4) according to the function can be divided into non-stick coating,Teflon paint,decorative coatings,anticorrosive coatings,conductive coatings,anti-rust coatings,high temperature coatings,temperature coating,thermal insulation coatings,fire coatings,

(5) According to the use can be divided into architectural coatings,canned paint,automotive coatings,aircraft coatings,home appliances coatings,wood coatings,bridge coatings,plastic coatings,paper coatings,marine coatings,wind power coatings,nuclear coatings.

(6) Home paint can be divided into interior paint,exterior paint,wood paint,metal paint,floor paint.

(7) According to the film performance points(anti-corrosion paint,insulating paint,conductive paint,heat-resistant paint.……)

(8) According to the film material(natural resin paint,phenolic paint,alkyd paint,amino paint,nitro-based paint,epoxy paint,chlorinated rubber paint,acrylic paint,polyurethane paint,Silicone resin paint,fluorocarbon resin paint,polysiloxane paint,vinyl resin paint.……)

a) Classified according to the type of base material:can be divided into organic coatings,inorganic coatings,organic -inorganic composite coating.Organic paint because of its use of different solvents,but also divided into organic solvent-based coatings and organic water(including water emulsion and water-soluble)two types of paint.Common paint in life is generally organic paint.Inorganic paint refers to the use of inorganic polymer materials based on the production of coatings,including water-soluble silicate,silica sol,silicone and inorganic polymer system.Organic-inorganic composite coating has two kinds of composite form,one is the production of organic materials and inorganic materials used as a base material,the formation of composite coatings;the other is organic coatings and inorganic coatings in the decorative construction of each other.

b) According to the decorative effect classification:can be divided into:1.Surface smooth and smooth surface coating(commonly known as flat coating),which is the most common kind of construction;2 surface sanding decorative effect of sand wall paint,such as real stone Paint;3.The formation of embossed three-dimensional decorative effect of the multi-layer coating,such as relief.

c) According to the use of parts in the building classification:divided into interior wall paint,exterior paint,floor coatings,doors and windows paint and ceiling paint.

d) According to the use of functional classification:can be divided into ordinary coatings and special functional architectural coatings(such as fire retardant coating,waterproof coating,mildew coating,road marking paint).

e) According to the use of color effects classification:such as metal paint,color paint(or called:solid paint),transparent varnish.

Paint classification method

There are many types of coatings,usually in the following types and applications:

(1) Alkyd paint,main use:general metal,wood,home decoration,agricultural machinery,automobiles,construction,etc.;

(2) Acrylic latex paint,main purposes:interior and exterior wall coating,leather coating,wood furniture painting,floor coating;

(3) Solvent-based acrylic paint,the main purposes:automotive,furniture,electrical,plastic,electronics,construction,floor coating;

(4) Epoxy paint,the main purposes:metal anti-corrosion,floor,automotive primer,chemical anti-corrosion;

(5) Polyurethane paint,main use:automotive,wood furniture,decoration,metal anti-corrosion,chemical anti-corrosion,insulating coating,instrumentation;

(6) Nitrocellulose lacquer,main use:wood furniture,decoration,metal decoration;

(7) Amino paint,main purposes:automotive,electrical appliances,instrumentation,wood furniture,metal protection;

(8) Unsaturated polyester paint,main purposes:wood furniture,chemical anti-corrosion,metal protection,floor;

(9) phenolic paint,insulation,metal anti-corrosion,chemical anti-corrosion,general decoration;

(10) Vinyl paint,main uses:chemical anti-corrosion,metal anti-corrosion,insulation,metal primer,exterior coatings.

Performance characteristics

1.Performance

(1) Opacity:The hiding power is usually expressed by the weight of the paint required to cover the specified black and white grid.The greater the weight,the smaller the hiding power.

(2) Coating adhesion:It means the adhesion of the coating film to the base layer.

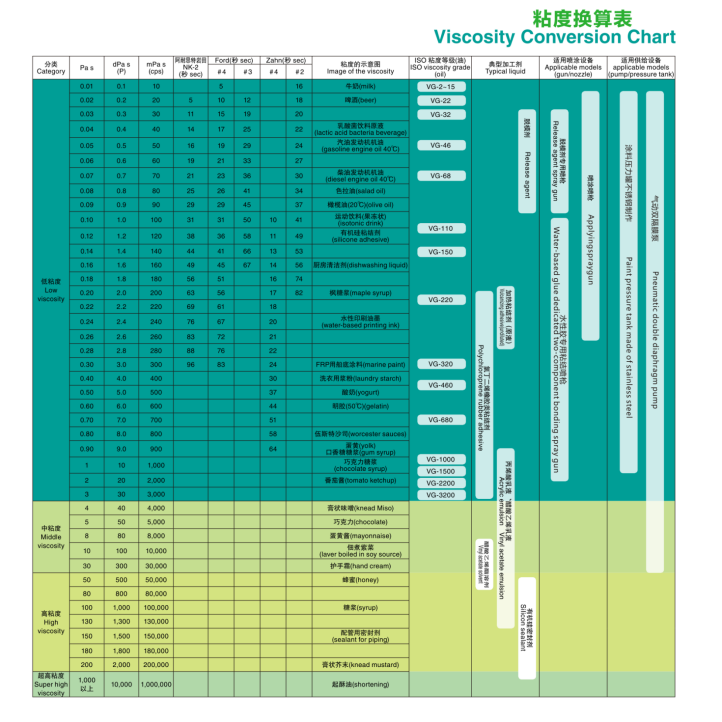

(3) Viscosity:The size of the viscosity affects the construction performance.Different construction methods require the coating to have different viscosities. (4)Fineness:The fineness directly affects the flatness and gloss of the surface of the coating film.

2.Features

(1)Pollution resistance

(2)Durability:including freeze-thaw resistance,scrub resistance,and aging resistance

(3)Alkali resistance:The decorative objects of the paint are mainly alkaline materials,so alkali is an important characteristic of the paint.

(4)Minimum film forming temperature:Each coating has a minimum film forming temperature,and different coatings have different minimum film forming temperatures.

(5)High temperature resistance,the paint has been developed from the original tens of degrees to today,it can withstand temperatures up to 1800Czš,energy-saving coatings.

Main role:

There are four points:Protect,decorate,disguise product defects and other special effects to enhance the value of the product.

Viscosity Basics

Viscosity,is the degree of stickiness is the primary function of the material,also known as dynamic viscosity,viscosity(lag)coefficient,the coefficient of friction.Different materials of different viscosity,for example at room temperature(20℃)and under atmospheric pressure,air viscosity 0.018mPa·s,gasoline 0.65mPa·s,the water is 1mPa·s,blood(37℃)of 4~15mPa·s,olive oil is 102 mPa·s,castor oil to 103mPa·s,honey is 104mPa·s,tar 106mPa·s,asphalt is 108mPa·s,and so on.The most common liquid viscosity roughly 1~1000m Pa·s,the viscosity of the gas roughly 1~10μPa·s.Pastes,gels,lotions and other complex liquids not easy to say.Some fats like butter or margarine very sticky,like a soft solid,rather than liquid flow.

Viscous drag force is fluid when subjected to shear stress or tensile stress deformation generated.In daily life,viscous like"viscosity"or"the fluid friction."Thus,water is"thin",with low stiction,and honey is"thick",with a high viscous force.Simply put,the lower the viscosity force(low viscosity)of the fluid,the better liquidity. Viscosity derived from the Latin word "mistletoe",meaning mistletoe.A viscous gel is called bird lime is made with mistletoe berries,can be coated on the twigs to capture birds.

Viscosity of the fluid due to the friction between adjacent layers to generate different movement speeds caused.Tube at the center of least resistance,the maximum flow rate of the liquid layer;wall near the viscous liquid layer by both resistance and wall friction effect,the minimum speed,moving at the speed of the liquid layer on the wall is zero(assuming no slip time).Therefore,some of the pressure in the vicinity(such as two pipe pressure differential)needed to overcome the frictional resistance between the layers to keep the fluid flow.Same speed mode,the stress should be proportional to the fluid viscosity.

In fact,there are two known amount of viscosity.Is called a dynamic viscosity,or simply viscosity absolute viscosity(to distinguish the other volume),but usually also called viscosity.Another known volume of kinematic viscosity(V indicated by symbol),which is the ratio of fluid viscosity and density.

Process,the rheological properties of the polymer mainly for the change in viscosity,the process according to the relationship of polymer viscosity and the flow stress or strain rate,the flow behavior of the polymer is divided into:Newtonian fluid-the viscosity is a constant;non-Newtonian fluid-the apparent viscosity μ is not constant.

spray gun Selected criteria

① What is the size of the workpiece to be sprayed?

Selection of small and large spray guns

● Small parts, toys, small items, car repair, etc... Small-sized

● Large components, vehicles, buildings, production lines spraying, large-scale spraying, etc... Large-scale

② Spray volume or area?

Selection of coating supply method (gravity type · suction type · pressurized type)

● For cases where a small amount of coating is sprayed and color changes occur frequently, the gravity type (G-type) coating cup is convenient to use.

For small and medium-sized spray applications, especially when multiple color changes are required, using an upward-suction (S-shaped) container is more convenient.

For processes such as large-scale coating on the same color products, it is convenient to use a pressure-fed (P-type) coating pump and pressurized container tanks.

③ Spray process and viscosity?

Selection of coating nozzle diameter and air gun cap

● For surface coating (finished product) spraying, special micronized coating particles are required. The selection of the air gun model must be made based on the coating output. Models with higher air volume, especially for metallic spraying, must have an air volume as large as possible. Selection of coating viscosity and nozzle diameter

● The nozzle diameter must be selected based on the coating viscosity. Generally, a small diameter is chosen for low viscosity coatings, and a large diameter is chosen for high viscosity coatings. ※ For pump-fed models, even with a small nozzle diameter, they can be used in a wide range of viscosity from low to high.

④ Selection of spray gun model

Selection of low-pressure models and universal models

● Considering environmental protection on Earth, spray guns with high spraying rate and low splashing have become the mainstream worldwide. The pressure inside the air cap of the pressure-fed spray gun is lower than 0.07 MPa (0.7 kgf/cm²), allowing for high micronization. Low-pressure spray guns reduce VOC emissions and improve the spraying operation environment.

⑤Is the air volume sufficient?

● The compressor produces approximately 100Vmin of air volume per 0.75KW (1HP). Please select the appropriate compressor based on the air usage of the spray gun. When choosing, the selected air volume = total spray gun usage × reserve coefficient (the safety value is 35%). Have you used the air source processor and pressure reducer?

● Moisture and oil are major enemies of spraying. The spray gun should be used at the pressure specified in the manual to fully utilize its performance. Air purifiers, pressure reducers or air transformers must be installed beside the spraying operator to adjust the clean air without oil and moisture to the specified pressure.

Address: 2nd Floor, Building 12,No.1438,Changan Section, Tai'an Road, Chang 'an Town, Dongguan City, Guangdong Province, China

QUICK LINKS

PRODUCT

CONTACT US

Copyright © 2025 Dongguan Changyuan Painting Accessories Co., Ltd. | All Rights Reserved 粤ICP备11059998号-1